Industrial Sewing Machines: Top Picks For Your Small Business

Jan 24,2024

Choosing the best industrial sewing machine for your business is an important step to ensuring optimal productivity, quality, and durability. The right machine can help you save time, reduce costs, and maintain consistency, enabling you to meet the demands of your clients without compromising on craftsmanship.

Choosing the best industrial sewing machine for your business is an important step to ensuring optimal productivity, quality, and durability. The right machine can help you save time, reduce costs, and maintain consistency, enabling you to meet the demands of your clients without compromising on craftsmanship.

By investing in the ideal equipment, you’ll be better equipped to handle various fabrics, stitching techniques, and projects, ultimately empowering your business to reach new heights of success and customer satisfaction.

There are several types of industrial sewing machines with each one catering to specific needs and applications. The machine you choose will depend on what kind of sewing contracts your business will be carrying out.

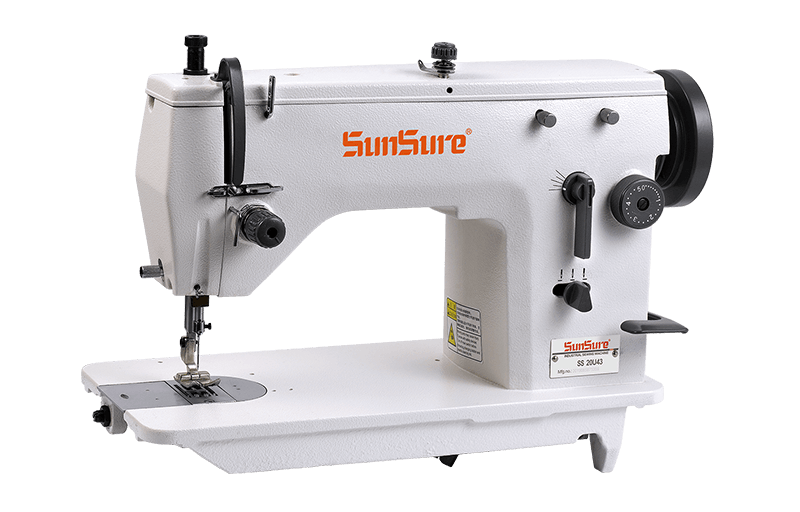

Flatbed Sewing Machines: Flatbed sewing machines are the most common type of industrial sewing equipment, designed to handle a wide range of fabrics and sewing needs. They resemble traditional home sewing machines, featuring a flat surface to support the fabric while stitching. Pair this type of machine with the best sewing table to achieve quality results.

Flatbed machines excel at producing straight, zigzag, and decorative stitches and are ideal for joining fabric pieces, hemming, and sewing simple garments. Their versatility and ease of use make them a popular choice for apparel, upholstery, and textile industries.

Cylinder Bed Sewing Machines: Cylinder bed sewing machines feature a narrow, cylindrical sewing surface, making them ideal for handling tubular or curved items such as sleeves, cuffs, and shoes. The unique shape allows for easy maneuvering of these difficult-to-sew shapes, enabling precise stitching even in tight spaces.

Cylinder bed machines are widely used in industries requiring specialized sewing tasks, including shoe manufacturing, leather goods, and heavy-duty applications where precision and accessibility are paramount.

Post Bed Sewing Machines: Post bed sewing machines have a raised sewing surface, resembling a vertical post, with the needle and feed mechanism mounted on top. The elevated design provides ample space for handling bulky or multi-layered fabrics, making it perfect for various things to make and sell for profit, including sewing bags, shoes, and upholstery.

Post bed machines are also favored in industries requiring intricate stitching or embellishments, such as attaching zippers, appliques, or decorative trims, thanks to their improved visibility and ease of fabric manipulation.

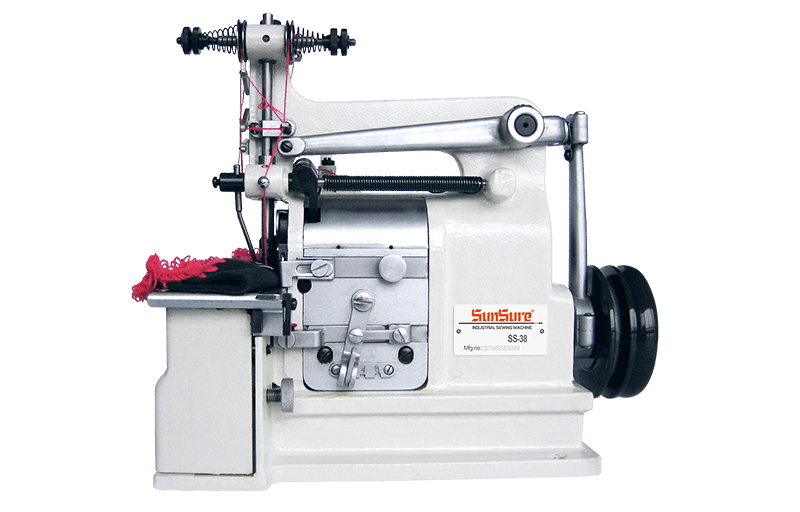

Overlock Sewing Machines: Overlock sewing machines, also known as sergers, are specifically designed to create clean, professional edges on fabric by trimming and enclosing raw edges within a thread enclosure. These machines use multiple threads to create a strong, stretchable seam, preventing fraying and ensuring durability.

Overlock machines are indispensable in the garment industry, where they are used for seaming, hemming, and edge-finishing on various materials, including knits and woven fabrics, contributing to polished, high-quality products.

Coverstitch Sewing Machines: Coverstitch sewing machines specialize in producing sturdy, stretchable seams and hems, making them ideal for working with knit or stretch fabrics. These machines use multiple needles and threads to create a professional finish, with a top row of straight stitches and a bottom row of interlocking loops.

Coverstitch machines are widely used in the apparel industry for hemming t-shirts, activewear, and swimwear, ensuring a comfortable, flexible fit while maintaining a neat, polished appearance.